Top Signs Your Air Dryer System Needs Replacement: Keep Your Fleet Running Smoothly

Posted by A&I Parts Center on 6th Jan 2025

Air brake systems are the unsung heroes of commercial fleets and heavy-duty vehicles, working tirelessly behind the scenes to ensure safe stopping power and reliable performance on the road. At the heart of these systems is an often-overlooked component: the air dryer. Charged with removing moisture from compressed air, air dryers prevent corrosion, freeze-ups, and other issues that can compromise both safety and efficiency. When these dryers begin to fail, they open the door to a range of problems—from increased maintenance costs to potentially catastrophic brake failures. Recognizing the early warning signs of a failing air dryer system is essential for fleet managers, mechanics, and vehicle owners who want to keep their operations running smoothly.

In this in-depth guide, we’ll explore the critical role air dryers play, the top indicators that it may be time for a replacement, and the risks of ignoring those signals. Finally, we’ll show you how A&I Parts Center can support your maintenance needs with high-quality air dryer systems and replacement cartridges designed to stand up to the rigors of heavy-duty use.

Understanding the Critical Role of Air Dryers

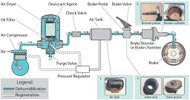

Before diving into the signs of a failing air dryer, it’s important to understand why these devices are so vital in commercial vehicles. Air brake systems work by compressing air and delivering it to various brake components, enabling controlled deceleration. In an ideal world, the air circulating through the system would be clean and free of moisture. However, the process of compressing air naturally generates water vapor. If that vapor isn’t removed, it can collect and freeze in brake lines, corrode sensitive parts, and reduce overall system effectiveness. This is where air dryers come into play.

An air dryer contains desiccant material—often silica gel or other moisture-absorbing substances—that extracts water and vapor from the compressed air before it reaches critical brake components. Some models also feature filters to remove oil and other contaminants. By doing so, air dryers help ensure that the air brake system remains dry, clean, and efficient. Modern air dryers also typically regenerate themselves by purging or cycling the desiccant, extending the unit’s operational life. When properly maintained, an air dryer can significantly reduce wear and tear on valves, lines, and other brake components, leading to fewer breakdowns, longer intervals between maintenance, and a safer driving experience.

Top Signs Your Air Dryer System Needs Replacement

Even the best-maintained air dryer won’t last forever. Over time, desiccant material becomes saturated or contaminated, seals and valves may wear out, and internal parts can be damaged by harsh operating conditions. Below are the most common red flags that indicate your air dryer is on its way out.

1.Excessive Moisture or Water in Air Tanks

One of the earliest and most telling signs of a failing air dryer is finding water or excessive moisture in the air tanks. Ideally, these tanks should remain relatively dry if the air dryer is functioning properly. A small amount of condensation can be normal, but if you’re seeing a significant collection of water when you drain the tanks—or if you notice water splattering from valves—it likely means the desiccant is no longer removing moisture effectively. Ignoring this can lead to frozen brake lines in winter or corrosion in warmer climates.

2.Frequent Purge Cycles or Unusual Purge Sounds

Air dryers are designed to purge at specific intervals, releasing trapped moisture and regenerating the desiccant. If you notice that your dryer is purging more often than usual, taking longer to complete a purge, or making unusually loud or erratic sounds during the cycle, it could be a sign of internal issues. Worn valves, clogged filters, or damaged seals may force the system to work harder to maintain dryness, resulting in abnormal purge patterns and noises.

3.Visible Corrosion or Rust Around Fittings and Lines

While some external corrosion can happen due to road salt or harsh weather, noticeable or accelerating corrosion near fittings, valves, or lines often indicates excessive moisture in the system. Over time, rust can break down metal components, leading to leaks, clogs, or outright failure of critical parts. If you’re constantly battling corrosion or replacing rusted lines, your air dryer might not be removing moisture as effectively as it once did.

4.Reduced Brake Performance or Longer Stopping Distances

A compromised air dryer can indirectly affect brake performance by allowing moisture to reach valves and brake chambers, which may cause them to freeze or operate erratically. Drivers may notice that the vehicle doesn’t stop as quickly as before, or that brakes are sluggish to release. These symptoms can also be caused by other brake system faults, but if the air dryer is underperforming, it’s a strong contributing factor.

5.High Desiccant Dust Levels

Desiccant material is intended to stay contained within the air dryer unit, absorbing moisture and occasionally releasing it during purges. Over time, however, desiccant can break down. If you’re finding desiccant dust in your air lines, around valves, or in the purge exhaust, it’s a sign that the dryer is deteriorating internally. This not only reduces the unit’s ability to remove moisture but can also clog or damage other components within the brake system.

6.Unusual Odors or Oil Discharge

Many air dryers include oil coalescing filters, but they’re not always 100 percent effective—especially as they wear down. A failing dryer might allow oil to pass into the air system. You could notice an oily residue in the purge exhaust or a burning smell if oil-laden air is exposed to high temperatures. Excessive oil can coat the desiccant, effectively “drowning” it and rendering it useless for moisture absorption.

7.Excessive Cycling of the Air Compressor

If your compressor is running too frequently or struggling to maintain pressure, it could indicate that the air dryer is clogged or offering too much backpressure. Overworked compressors not only increase fuel consumption but also lead to increased wear on critical engine components. Sometimes, a simple clogged filter can be the culprit, but if replacing or cleaning the filter doesn’t help, the dryer itself may need attention—or replacement.

Risks of Ignoring Failing Air Dryer Signs

Neglecting the above warning signs can have far-reaching consequences for both safety and finances. Commercial fleet operations in particular stand to lose significantly if multiple vehicles suffer from failing air dryers. Here’s why prompt action is crucial:

Extend the Life of Your Braking System: Replacement and Maintenance

Replacing a failing air dryer system isn’t just a matter of swapping one part for another; it’s an investment in long-term vehicle health and reliability. New or updated air dryers use advanced desiccant materials and improved purge and regeneration technologies, extending service intervals and lowering overall maintenance expenses. For fleets operating in extreme climates—like freezing northern winters or hot, humid southern summers—upgrading to a high-quality unit can drastically reduce weather-related brake issues.

Regular maintenance also plays a significant role in prolonging the life of your air dryer and the brake system as a whole. While it won’t prevent inevitable wear, routine inspections, filter changes, and periodic desiccant replacements can delay full-system replacements. Implementing a scheduled maintenance plan for your air dryers—and sticking to it—can prevent minor issues from spiraling into major breakdowns.

Keep Your Fleet Running Smoothly with A&I Parts

When it comes time to replace or upgrade an aging air dryer, A&I Parts Center is your go-to partner. We understand the demands of commercial fleets, agricultural equipment, and heavy-duty machinery, offering a range of air dryer systems and replacement cartridges that prioritize durability, performance, and ease of installation.

1.Complete Air Dryer Assemblies: Whether you need a standard replacement or a heavy-duty unit designed for extreme environments, A&I Parts Center has options tailored to your specific needs.

2.Replacement Cartridges and Filters: Sometimes, a new cartridge or filter is all that’s required to restore your air dryer’s efficiency. We carry multiple types and sizes to fit various models, ensuring you get the correct part every time.

3.Expert Guidance and Support: Not sure which air dryer best suits your fleet? Our knowledgeable team can help you compare features, compatibility, and price points.

4.High-Quality Manufacturing: Every air dryer system and cartridge we offer is built with rigorous quality standards, ensuring that the parts you install are designed to withstand the toughest operating conditions.

5.Competitive Pricing and Fast Shipping: We understand that downtime can be costly. That’s why we strive to offer competitive pricing and quick shipping options to get your vehicles back on the road as soon as possible.

If you’ve noticed any of the warning signs mentioned—excessive moisture in tanks, corrosion around brake lines, unusually frequent purge cycles, or reduced brake performance—it’s time to take proactive steps. Don’t wait until a minor inconvenience turns into a full-blown brake failure. Head over to A&I Parts Center today and explore our selection of air dryer systems and replacement cartridges. Each product is designed with durability and efficiency in mind, ensuring your fleet can handle the toughest jobs without being sidelined by costly breakdowns.

Replacing a failing air dryer is a practical, cost-effective measure that not only safeguards your drivers and vehicles but also optimizes your operation. By acting swiftly, you’ll avoid expensive repairs, improve overall safety, and maintain the performance levels your customers and drivers expect. When it comes to heavy-duty equipment and commercial fleets, an ounce of prevention is worth a pound of cure—and a high-quality air dryer from A&I Parts Center is a wise investment in your long-term success.